Advanced microscopy maps stress in fusion reactor welds

Apr. 30, 2025.

2 mins. read.

Interactions

Researchers use cutting-edge imaging to study P91 steel welds, ensuring safer, longer-lasting fusion reactors for clean, low-carbon energy.

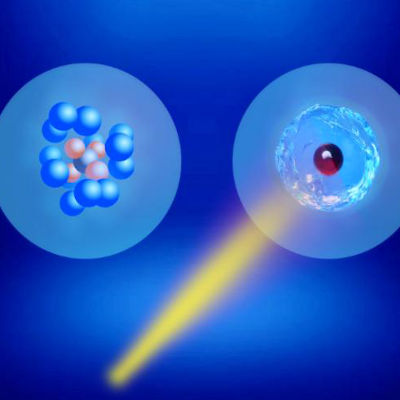

Researchers from the University of Surrey, UK Atomic Energy Authority, National Physical Laboratory, and TESCAN study welded metals for fusion reactors. They focus on P91 steel, a strong, heat-resistant metal for future reactors. Fusion reactors create energy by fusing atoms, like the sun. This process, called fusion energy, produces minimal radioactive waste.

The study, published in Journal of Materials Research and Technology, examines welds in P91 steel. Welds are joints where metals fuse during manufacturing. Hidden stresses, known as residual stress, weaken these joints. Residual stress is internal pressure locked in metals after welding.

The researchers use a plasma focused ion beam with digital image correlation, or PFIB-DIC, to map stress. PFIB-DIC is an advanced imaging method using ion beams and cameras to measure tiny deformations. It reveals stress in narrow weld zones, called heat-affected zones, too small for older methods. Results show stress affects P91 steel’s performance. Beneficial stress hardens some areas, making them stronger. Harmful stress softens others, causing bending or breaking. At 550°C, a temperature reactors face, the steel loses over 30% strength and becomes brittle. Brittle means it breaks easily.

Ensuring Safer Fusion Reactors

This method tests welds under real reactor conditions, unlike past studies at lower temperatures. Findings help design safer reactors, like the UK’s STEP and EU’s DEMO projects. The data supports finite element simulation models. It also aids machine learning tools that predict outcomes, cutting experimental costs. The approach applies to many metal joints, improving safety in extreme environments.

Fusion energy offers clean, reliable power, reducing carbon emissions and energy costs. Unlike traditional nuclear power, it produces short-lived waste. The research advances fusion reactor design, ensuring components last longer. TESCAN’s FIB-SEM instruments, which are microscopes for nanoscale work, enable precise stress measurements. This work sets a blueprint for assessing welds, bringing fusion power closer to reality. It supports commercial fusion, delivering secure, low-carbon electricity at scale.

Let us know your thoughts! Sign up for a Mindplex account now, join our Telegram, or follow us on Twitter.

.png)

.png)

.png)

0 Comments

0 thoughts on “Advanced microscopy maps stress in fusion reactor welds”