Microfabrication on living organisms

Apr. 22, 2025.

2 mins. read.

3 Interactions

Scientists use advanced techniques to create tiny metal patterns on living tardigrades, enabling new bio-inorganic hybrid systems.

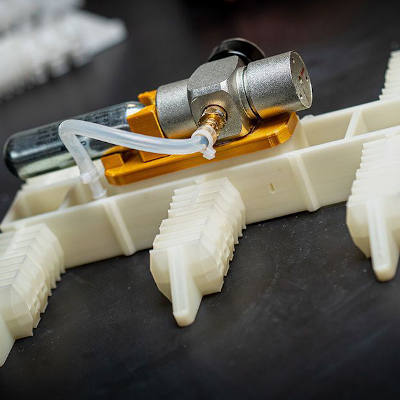

Nanotechnology advances allow scientists to create tiny, complex patterns on materials. Techniques like ultraviolet lithography, electron beam lithography, and nanoimprinting shape surfaces precisely. Ultraviolet lithography uses light to carve patterns. Electron beam lithography employs electron beams for finer details. Nanoimprinting presses molds to form structures.

These methods work well on non-living materials but struggle with living organisms. Biological systems, like animal skin, are delicate and complex. Traditional fabrication harms them due to harsh conditions. Integrating functional materials into living interfaces remains challenging.

Working toward a solution, researchers at Westlake University have explored microfabrication on tardigrades, also called water bears.

Tardigrades survive extreme conditions, including freezing, heat, radiation, and dehydration. The researchers used semiconductor thin-film deposition, specifically magnetron sputtering and electron beam evaporation. Magnetron sputtering sprays metal particles onto surfaces. Electron beam evaporation heats metals to deposit them as films. They applied these techniques during the tardigrades’ cryptobiotic state, when metabolism nearly stops. This state protected the tardigrades during fabrication.

Breakthrough in bio-inorganic systems

After depositing metal films, the researchers hydrated the tardigrades. The creatures resumed normal activity, and the films cracked into stripe-like patterns. Different metals gave unique traits. Magnetic metals allowed movement control via external magnetic fields. Tardigrades rotated, rolled, or shifted as directed. This control shows the potential for bio-inorganic hybrid systems, blending living and non-living materials.

The study opens doors for microfabrication on living organisms. Advanced techniques, like 3D printing, could create even more detailed patterns. 3D printing builds structures layer by layer. Using light, electricity, or heat, scientists can target specific areas precisely. These methods promise breakthroughs in bioelectronic devices, which combine electronics with biology, and living robots, which merge organic and synthetic parts. The research highlights nanotechnology’s role in uniting inorganic materials with living systems, paving the way for innovative applications.

The researchers have descrived the methods and results of this study in a paper published in Science Bulletin.

Let us know your thoughts! Sign up for a Mindplex account now, join our Telegram, or follow us on Twitter.

.png)

.png)

.png)

0 Comments

0 thoughts on “Microfabrication on living organisms”