How to 3D-print a complex robot at high precision and speed

Nov. 16, 2023.

6 min. read

7 Interactions

3D-printing fully-formed robots

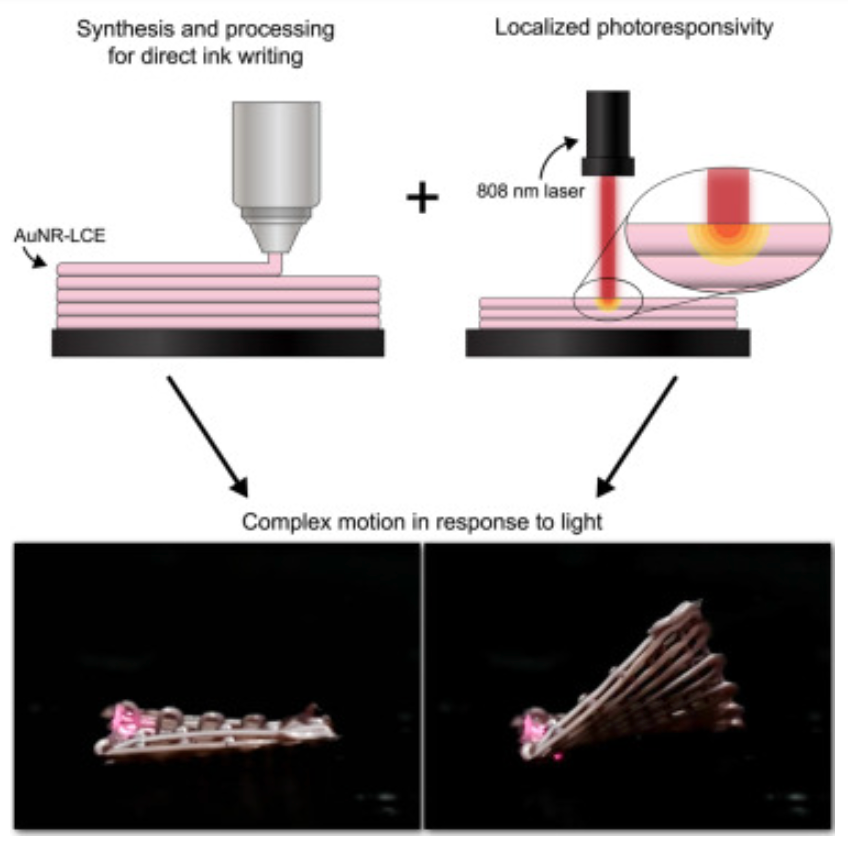

Machine vision enables multi-material 3D printers to create complex shapes. But making functioning objects from multiple materials in a single print-run has proved challenging.

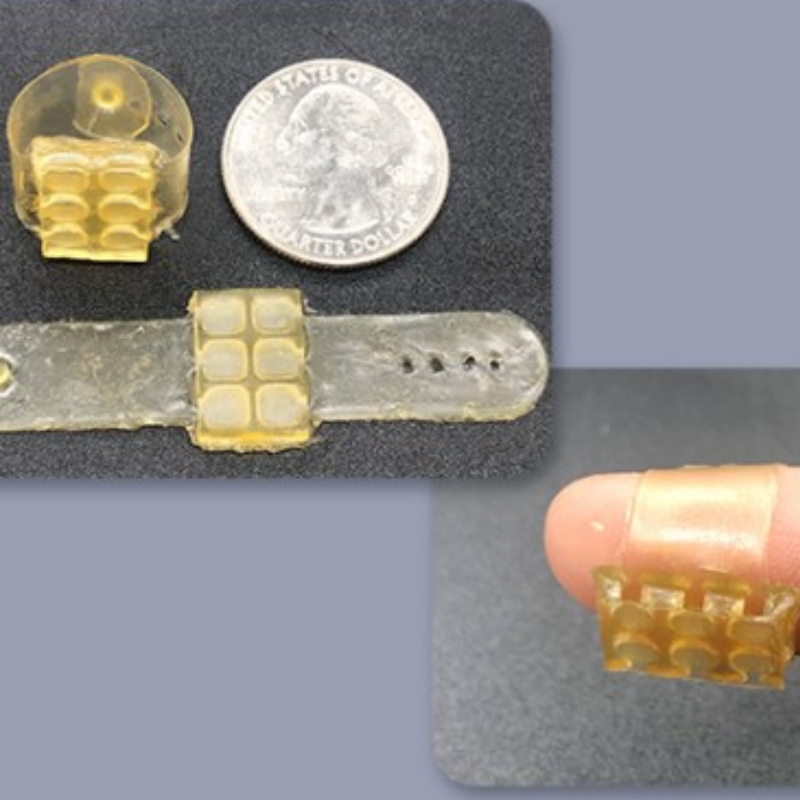

An MIT team has now combined inkjet printing with an error-correction system guided by machine vision. They used this method to make a bio-inspired, 3D-printed robotic gripper that’s shaped like a human hand and controlled by a set of reinforced, flexible tendons.

Tendon-driven robotic hand has 19 independently actuatable tendons, soft fingers with sensor pads, and rigid, load-bearing bones (credit: Wojciech Matusik, Robert Katzschmann, Thomas) Buchner, et al )

They combined soft and rigid plastics to make mechanical bones, ligaments, and tendons, as well as a pump based on a mammalian heart.

Limited types of materials with current systems

With 3D inkjet printing systems, engineers can fabricate hybrid structures that have soft and rigid components, like robotic grippers that are strong enough to grasp heavy objects but soft enough to interact safely with humans.

These multimaterial 3D printing systems use thousands of nozzles to deposit tiny droplets of resin, which are smoothed with a scraper or roller and cured with UV light. But the smoothing process could squish or smear resins that cure slowly, limiting the types of materials that can be used.

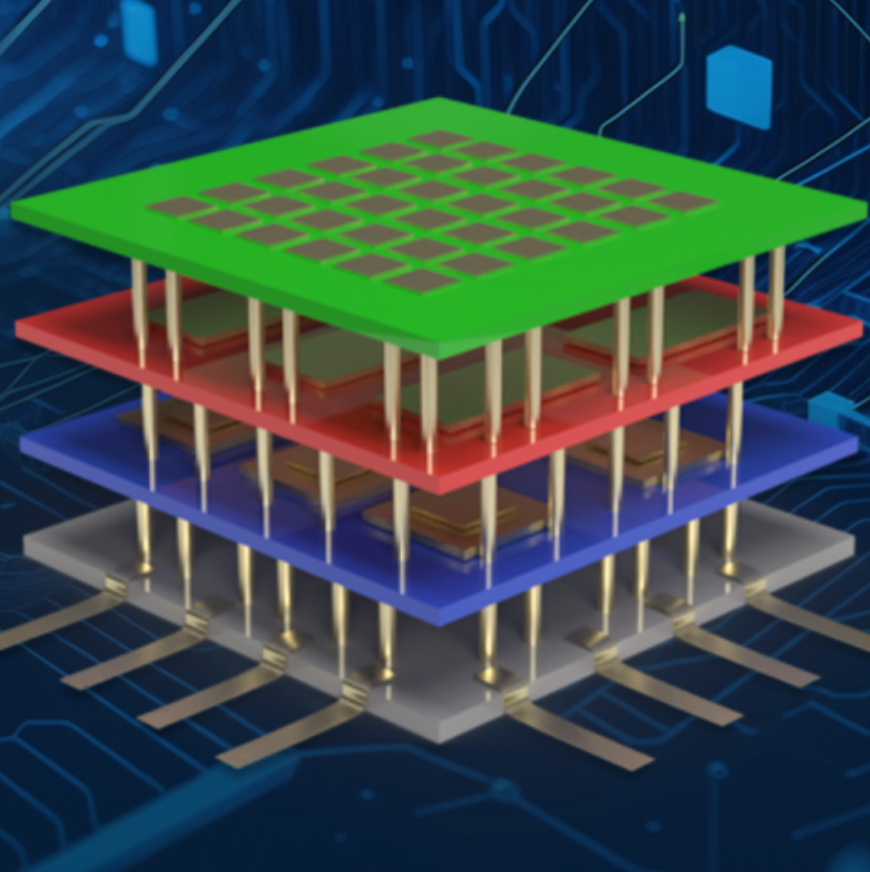

Their printer uses computer vision to automatically scan the 3D printing surface and adjust the amount of resin each nozzle deposits in real time to ensure no areas have too much or too little material.

Since it does not require mechanical parts to smooth the resin, this contactless system works with materials that cure more slowly than the acrylates which are traditionally used in 3D printing. Some slower-curing material chemistries can offer improved performance over acrylates, such as greater elasticity, durability, or longevity.

660 times faster

In addition, the automatic system makes adjustments without stopping or slowing the printing process, making this production-grade printer about 660 times faster than a comparable 3D inkjet printing system.

“Our key insight here was to develop a machine vision system and completely active feedback loop. This is almost like endowing a printer with a set of eyes and a brain, where the eyes observe what is being printed, and then the brain of the machine directs it as to what should be printed next,” says co-corresponding author Wojciech Matusik, a professor of electrical engineering and computer science at MIT who leads the Computational Design and Fabrication Group within the MIT Computer Science and Artificial Intelligence Laboratory (CSAIL).

He is joined on the paper by lead author Thomas Buchner, a doctoral student at ETH Zurich, co-corresponding author Robert Katzschmann, PhD ’18, assistant professor of robotics who leads the Soft Robotics Laboratory at ETH Zurich; as well as others at ETH Zurich and Inkbit. The research will appear in Nature.

This paper builds off a low-cost, multimaterial 3D printer known as MultiFab that the researchers introduced in 2015. By utilizing thousands of nozzles to deposit tiny droplets of resin that are UV-cured, MultiFab enabled high-resolution 3D printing with up to 10 materials at once.

“Vision-controlled jetting” for composite systems and robots

With this new project, the researchers sought a contactless process that would expand the range of materials they could use to fabricate more complex devices.

The computer vision system converts the image into a high-resolution depth map, a computation that takes less than a second to perform. It compares the depth map to the CAD (computer-aided design) model of the part being fabricated, and adjusts the amount of resin being deposited to keep the object on target with the final structure.

The automated system can make adjustments to any individual nozzle. Since the printer has 16,000 nozzles, the system can control fine details of the device being fabricated.

“Geometrically, it can print almost anything you want made of multiple materials. There are almost no limitations in terms of what you can send to the printer, and what you get is truly functional and long-lasting,” says Katzschmann.

The level of control afforded by the system enables it to print very precisely with wax, which is used as a support material to create cavities or intricate networks of channels inside an object. The wax is printed below the structure as the device is fabricated. After it is complete, the object is heated so the wax melts and drains out, leaving open channels throughout the object.

Because it can automatically and rapidly adjust the amount of material being deposited by each of the nozzles in real time, the system doesn’t need to drag a mechanical part across the print surface to keep it level. This enables the printer to use materials that cure more gradually, and would be smeared by a scraper.

Superior materials

The researchers used the system to print with thiol-based materials, which are slower-curing than the traditional acrylic materials used in 3D printing. However, thiol-based materials are more elastic and don’t break as easily as acrylates. They also tend to be more stable over a wider range of temperatures and don’t degrade as quickly when exposed to sunlight.

“These are very important properties when you want to fabricate robots or systems that need to interact with a real-world environment,” says Katzschmann.

Complex devices now possible

The researchers used thiol-based materials and wax to fabricate several complex devices that would otherwise be nearly impossible to make with existing 3D printing systems. For one, they produced a functional, tendon-driven robotic hand that has 19 independently actuatable tendons, soft fingers with sensor pads, and rigid, load-bearing bones.

“We also produced a six-legged walking robot that can sense objects and grasp them, which was possible due to the system’s ability to create airtight interfaces of soft and rigid materials, as well as complex channels inside the structure,” says Buchner.

The team also showcased the technology through a heart-like pump with integrated ventricles and artificial heart valves, as well as metamaterials that can be programmed to have non-linear material properties.

“This is just the start. There is an amazing number of new types of materials you can add to this technology. This allows us to bring in whole new material families that couldn’t be used in 3D printing before,” Matusik says.

The researchers are now looking at using the system to print with hydrogels, which are used in tissue-engineering applications, as well as silicon materials, epoxies, and special types of durable polymers.

They also want to explore new application areas, such as printing customizable medical devices, semiconductor polishing pads, and even more complex robots.

This research was funded, in part, by Credit Suisse, the Swiss National Science Foundation, the Defense Advanced Research Projects Agency (DARPA), and the National Science Foundation (NSF).

Nature Podcast: How to 3D-print fully-formed robots

Citation: Buchner, T. J., Rogler, S., Weirich, S., Armati, Y., Cangan, B. G., Ramos, J., Twiddy, S. T., Marini, D. M., Weber, A., Chen, D., Ellson, G., Jacob, J., Zengerle, W., Katalichenko, D., Keny, C., Matusik, W., & Katzschmann, R. K. (2023). Vision-controlled jetting for composite systems and robots. Nature, 623(7987), 522-530. https://doi.org/10.1038/s41586-023-0668

Let us know your thoughts! Sign up for a Mindplex account now, join our Telegram, or follow us on Twitter.

.png)

.png)

.png)

2 Comments

2 thoughts on “How to 3D-print a complex robot at high precision and speed”

Lots of cool tech to like

🟨 😴 😡 ❌ 🤮 💩

That is so cool that I'm speechless

where can I get one?

🟨 😴 😡 ❌ 🤮 💩